Custom Aluminum Fabrication

Aluminum Fabrication at Star Extruded

Over our 40+ years in business, Star has developed a niche for supplying fabricated and machined components, ready to assemble for our customers. Our on-site 100,000 Sq Ft fabrication facility, Star Fab, has processes for general fabrication, CNC machining (Vertical and Horizontal), long-length material machining, and assembly services. Our offering of rapid prototypes and short run samples enhances our value proposition in this area.

Aluminum Fabrication Process

Aluminum fabrication is the manufacturing process of converting aluminum extrusions into finished parts for your application. Star utilizes a wide variety of procedures and techniques to configure aluminum extrusions by way of cutting, bending, deburring, welding, machining and forming to assemble your end product. Aluminum alloys offer unmatched advantages over other alternative materials that allow our team to fabricate a variety of product types.

Aluminum Fabrication Capabilities

ISO 9001:2015 certified

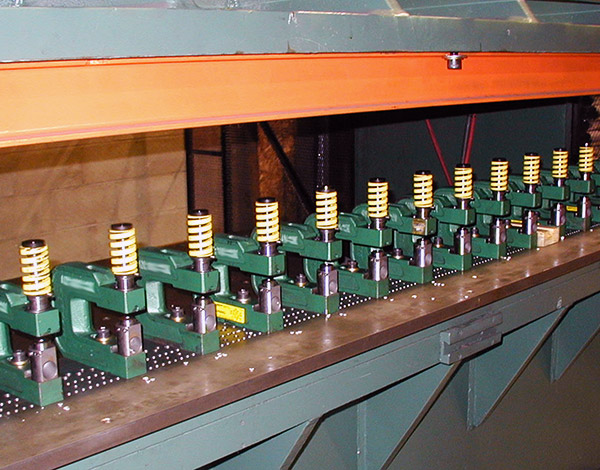

Conventional punch presses – all OSHA-compliant

20 to 150-ton punch presses

Machining capability from short lengths up to 20 ft+ long lengths

.400” to 20’ cut size lengths with + .010” tolerances

Horizontal and vertical machining centers

4th-axis machining

Precision straight and miter cuts

Compound miters and V-notch saws

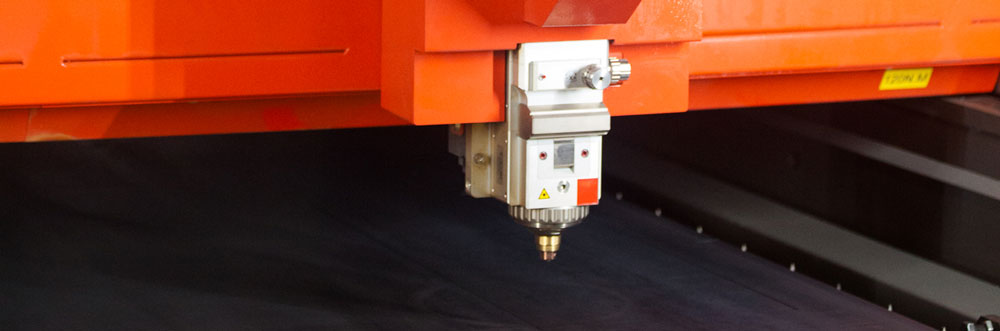

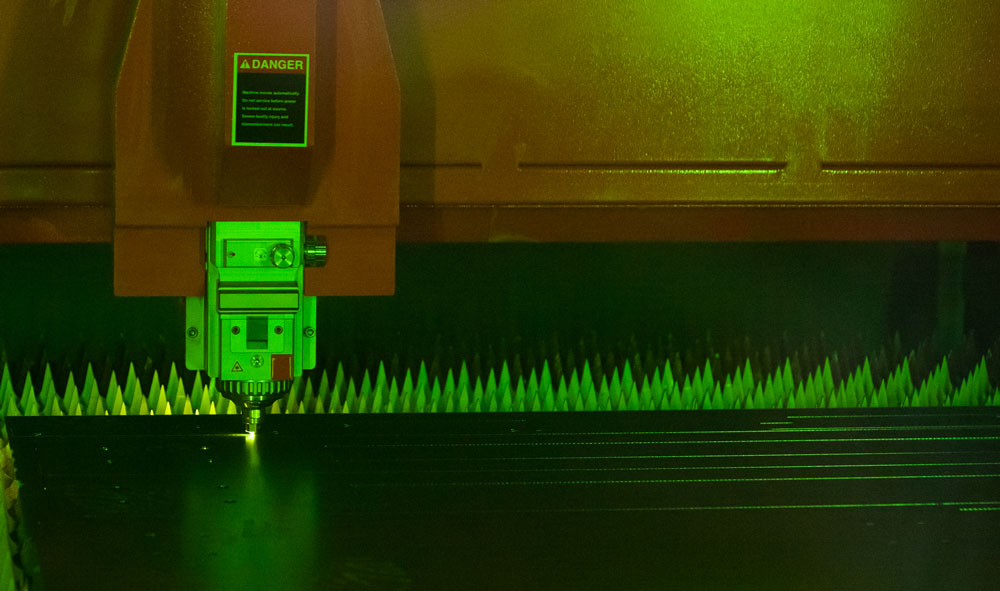

Laser Cutting

Sheet Metal Forming

Vibro deburr and lineal deburr

Punching and notching machines

Drilling

Countersinking

Counterboring

Tapping

Welding

Imprinting

Embossing and debossing

Engraving

Private labeling

Complete assembly

Aluminum’s Unique Properties

Aluminum is lightweight, durable, ductile and versatile enough to be utilized in many different applications across a wide range of industries. With superior mechanical properties, aluminum is easier to work with and often has a much higher strength to weight ratio.

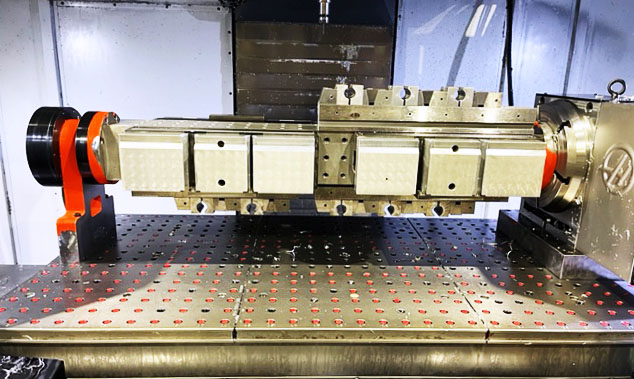

CNC Machining for Aluminum Extrusion

We have thirteen CNC machines that include vertical and horizontal machining. Our knowledgeable team reviews each project in-depth, validates manufacturability and ensures your parts are processed with maximum efficiency without compromising quality.

Our thirteen CNC machines also have 4th-axis capabilities. 4th-axis machining offers capabilities similar to 3rd-axis, but with additional rotary movement around the X-axis. This allows us to mill aluminum extrusions on multiple axes without having to change tooling, which increases productivity.

Designing Your Aluminum Fabrication Project

Whether you come to Star with a full fabrication print or just an idea, we work with you to achieve your fabrication and design requirements. We utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to help create and execute your fabrication needs.

Custom Aluminum Part Fabrication

Our team of experts evaluate your project and determine the best approach for tooling and machining necessary to meet requirements efficiently. Our fabrication facility is equipped with some of the most advanced fabrication equipment and machinery.

Aluminum Extrusion Finishing & Complete Assembly

The final step in the aluminum fabrication process is to verify the fabricated part meets specifications and is ready for use. We ensure the fabricated parts meet required specifications through meticulous inspection that includes creating custom gauging to ensure the fit and function of each part when necessary. Additionally, we have the ability to provide finishing and assembly services, such as powder coating, anodizing and wet paint.

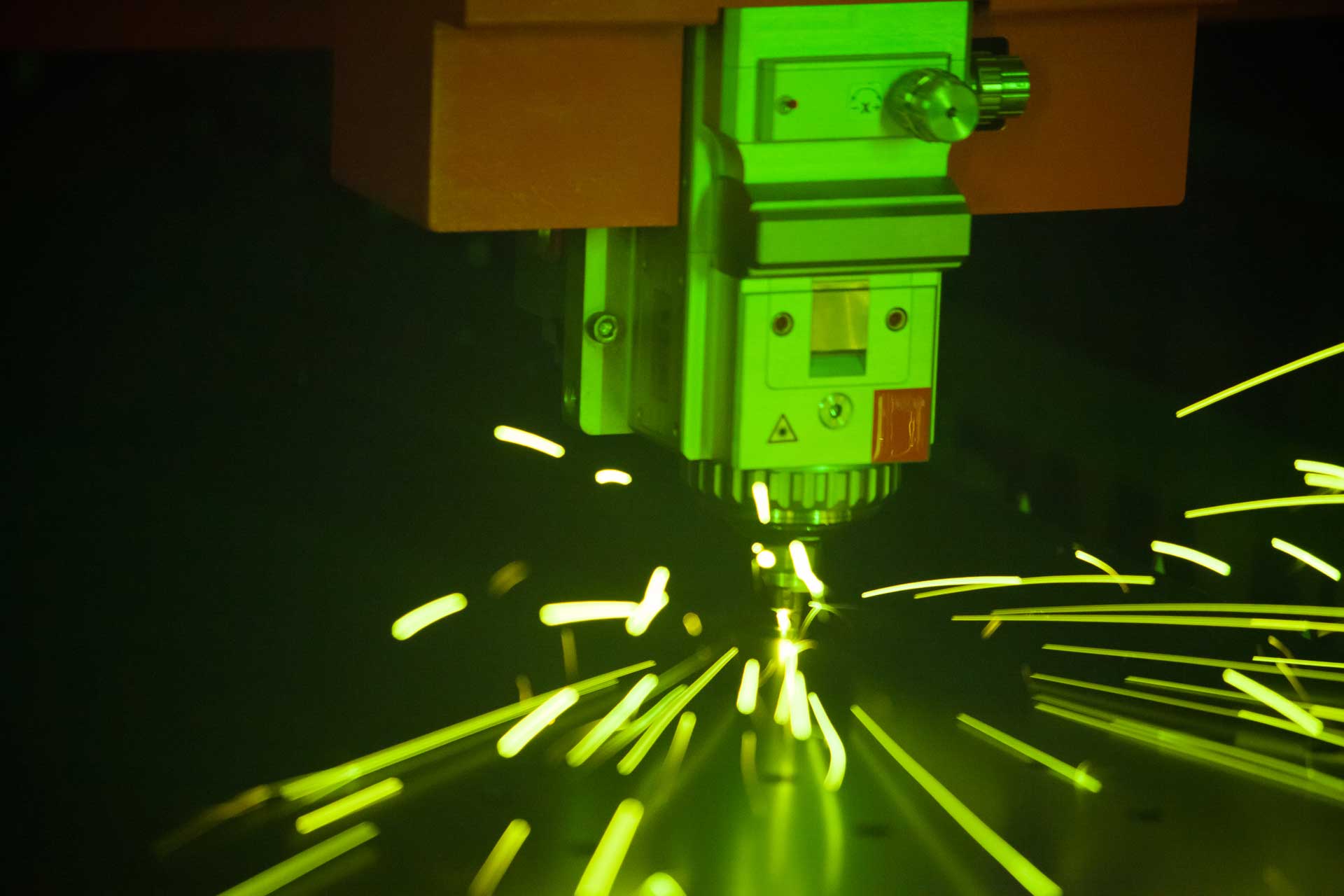

Laser Cutting Machinery

Our laser cutting capabilities ensure greater accuracy and speed, saving you time and money. We can pinpoint cut dimensions precisely and produce part nesting, as well as laser head path speeds. Fast, detailed cuts mean fast lead times and a versatile and high-quality part satisfying a wide range of applications.

- Laser cutting material capabilities:

- Hot rolled and cold rolled steel up to 3/4″ thick

- Galvanized steel up to 1/8″ thick

- Stainless steel up to 1/2″ thick

- Aluminum up to 7/16″ thick

- Brass and copper up to 1/4″ thick

- Table capacity for sheet sizes up to 60” x 120”

Equipped with dual upper and lower pallets for quick table changes

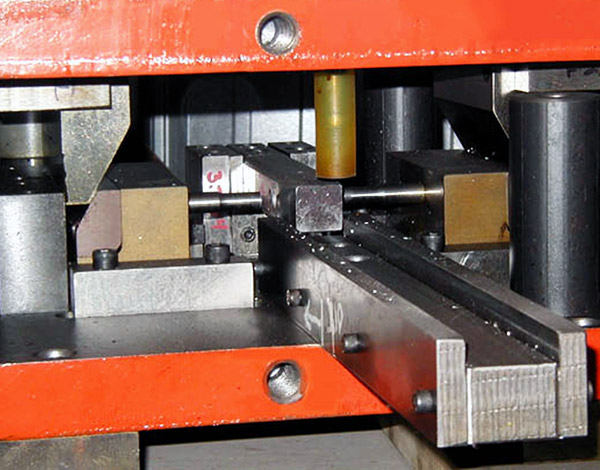

Press Brake Equipment

Press brake machines deliver exceptional precision and durability in sheet metal bending. Cutting-edge technology delivers quick-change capabilities, automated CNC back gauges and the capacity for unmatched versatility and increased output, consistency and accuracy.

- 248 ton press

- 160” bed length

- 4-axis back gauge

- DNC-controlled hydraulic crowning

- Segmented tooling for box forming

Can Star Extruded Shapes Fabricate My Part?

Our dedicated team will promptly review your inquiry and get back to you with the information and assistance you require.

Thank you for considering Star Extruded Shapes for your aluminum extrusion and fabrication needs. We look forward to serving you with our expertise and commitment to quality.