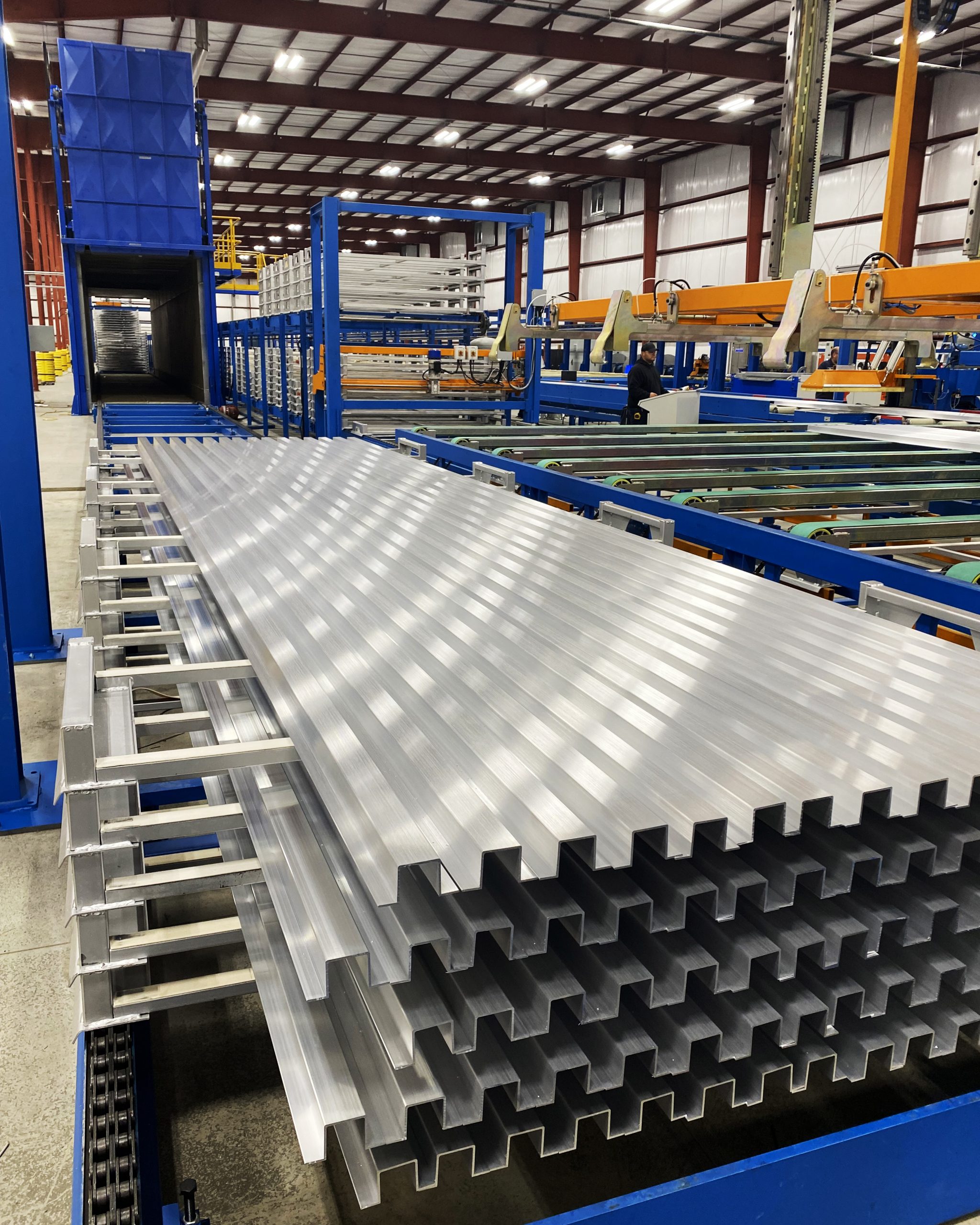

The New Building is Finished & Press is Fully Operational, we are ready for your orders!

The new line is fully automated & allows for the extrusions to go through all of the processes (extrusion, stretching, cutting & heat treatments) without being touched until the material is packed. This ensures less potential for human error & allow us to run more efficiently to get you your orders quickly and in pristine condition. The press also has inline packing stations, to immediately pack materials once they exit the press. Furthermore, the new buildings additional square footage will provide warehouse space for potential stocking programs, in the near future.

Once we have fully implemented the Stocking Programs Onsite, it will give us the ability to store your orders & materials efficiently, if needed & ensure timely deliveries.

Capabilities of our new 4th press:

3,000 ton press

9 inch circle size

Adding 20-25 million pounds of capacity

Max lengths 25-35 foot

Max weight per foot 10 lbs

Max profile width 17 inches

Max profile height 9 inches

Talk to one of our knowledgable sales reps today, to get an RFQ or discuss how Star can provide a seamless process from start to finish.