What do aerospace, healthcare, oil and gas, military and defense and industrial manufacturers all have in common? The designers, the engineers and the builders of these industries entrust CNC (computer numerical control) precision machining to make dreams and visions – real and robust solutions, vital to business operations and moving the industry forward. Manufacturing has changed, to a great degree, because of CNC machines and the ability to reduce production costs, create faster lead times, ensure better accuracy and enhanced output.

WHAT IS CNC MACHINING?

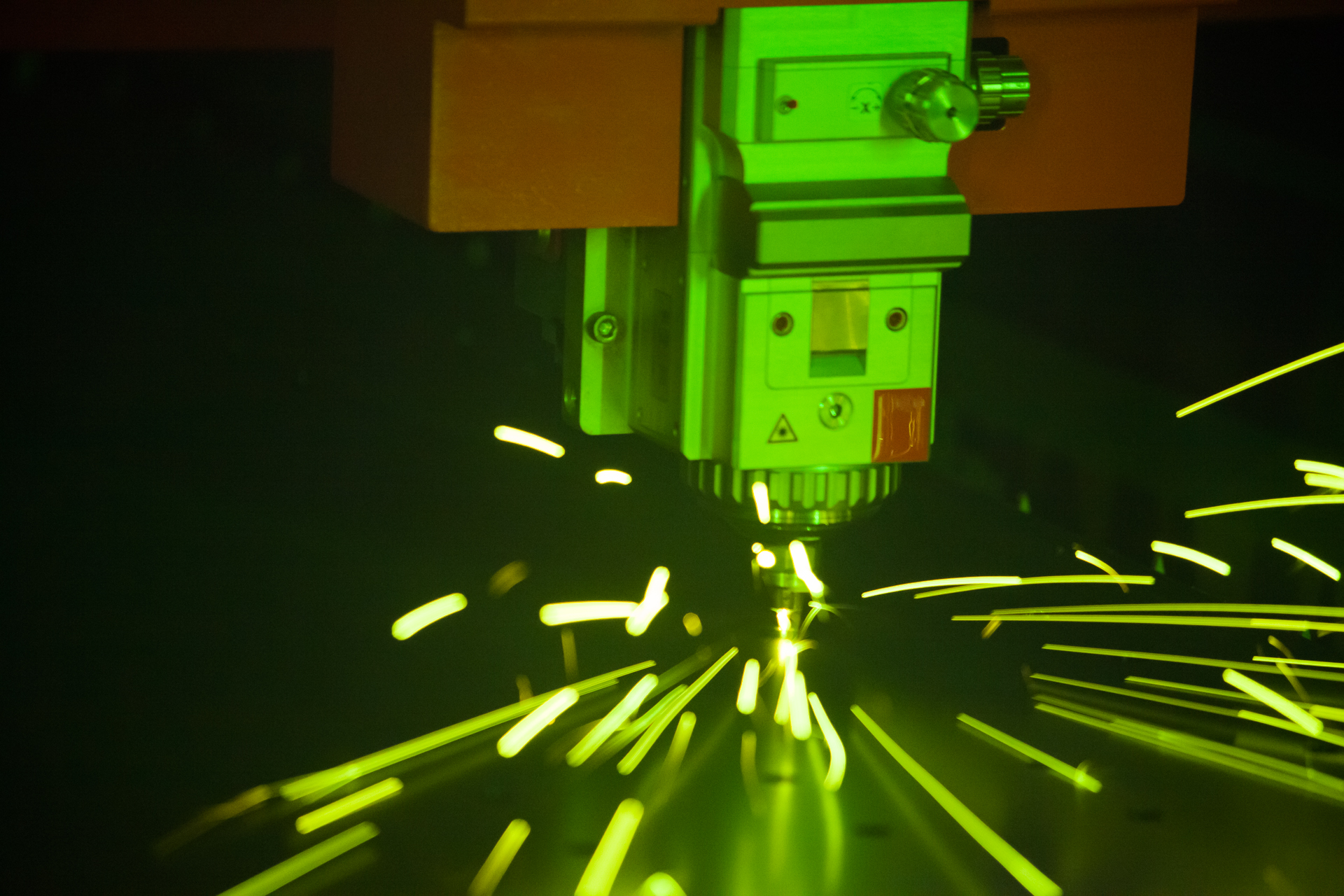

It’s a process in manufacturing where pre-programmed computer software orchestrates the movement of plant tools and machinery. Instructions are inserted into the CNC machine through a CAD file and translated into a precise set of sequential commands. The application is used to automate a wide range of techniques, which for the longest time, were conducted manually, including milling, water jet cutting and laser cutting materials. This level of automation means machines can operate around the clock with the highest regard for worker safety. CNC machines utilize multiple axis points, each operating with at least three-axis cuts: X (vertical), Y (horizontal) and Z-axis (depth). While most of the machines found on the shop floor have a moving bed, three-axis machinery remains in the same position. At the same time, the cutter operates along the X, Y and Z plane simultaneously. This multifunctional capability is best suited for mechanical parts that do not require a lot of detail and scale (i.e., milling slots, drilling holes, cutting sharp edges and creating customized parts). Unlike other equipment, three-axis CNC machines only need one workstation to complete a task, such as cutting into a shallow piece of material. However, three-axis has its limitations, especially when it comes to a more in-depth, complex product.

INTRODUCING FOUR-AXIS CNC PRECISION MACHINING

Like three-axis, a four-axis (A-axis) CNC precision machine presents the same capabilities, but with one key differentiator – an extra cutting direction for increased precision and accuracy of advanced machining. This added rotary movement around the X-axis allows cutting to happen along all axes and vertical axis separately – beneficial when holes or cuts need to be made on the side of a workpiece or around odd angles, such as a cylinder. The rotation opens the door to produce multiple face workpieces more efficiently and simultaneous rotating and milling, which are necessary to perform intricate spirals and contours. This level of capability and efficiency means industries of all types, including architecture, oil and gas, construction, military and more favor utilizing four-axis machining to achieve product designs.

BENEFITS OF FOUR-AXIS CNC MACHINES

Four-axis machinery presents advantages over other three-axis machines – being used for intermittent cutting, continuous cutting or engraving curved services. Additional benefits of four-axis CNC machines include:

Higher Accuracy

Four-axis CNC machinery provides multiple faces to access without moving the piece out of a fixture, producing highly accurate features. This level of accuracy results in less scrap and a rise in profits.

Achieve Complexity in Part Designs

The most common reason to utilize such a machine is the ability to accomplish complex parts. Four-axis machinery, built for detailed work, can access odd angles without designing complicated fixtures.

Faster Part Production Time

Cycle time per part is reduced due to collective operations being performed in a single clamping. Four-axis does not have to be stopped to turn the part in the fixture, meaning no downtime to change tooling or having an operator to rotate the component manually.

Four-axis CNC machines can be used for different purposes, including creating art, medical equipment, advertising design, teaching, technology research, industrial parts, prototype building and more.

GET FOUR-AXIS MACHINING SERVICES FROM THE EXPERTS AT STAR

At Star Extruded Shapes, Inc., we offer the very best in CNC machines (12, in fact), including four-axis capabilities, to ensure you get the highest quality part, on-time and at the most competitive price.